Allied Concrete trailblazing sustainability in ready mixed concrete

29th May 2018

Allied Concrete is committed to ongoing improvement in sustainable practice, and was the first company in the Australasian region to publish an EPD.

We spoke to Allied Concrete’s Technical Project Manager Chris Munn about the decision to produce and EPD and how it has been used since published.

Why did Allied Concrete decide to produce an EPD?

We have always had a focus on environmental programmes that positioned us as an innovator in the sustainability area for ready-mixed concrete. That has seen us lead the way in the use of recycled concrete as an aggregate in New Zealand, the use of recycled crushed glass as a sand replacement, the use of recycled paint as a concrete admixture and of course, the EPD.

How did you find the process?

The process was more involved that we thought it would initially be; it required a very detailed data collection system that took some time to undertake using a person solely dedicated to that task. As we were one of the first to obtain a concrete EPD using the European rule-set we were trailblazing the process.

How has the EPD been used since it was published?

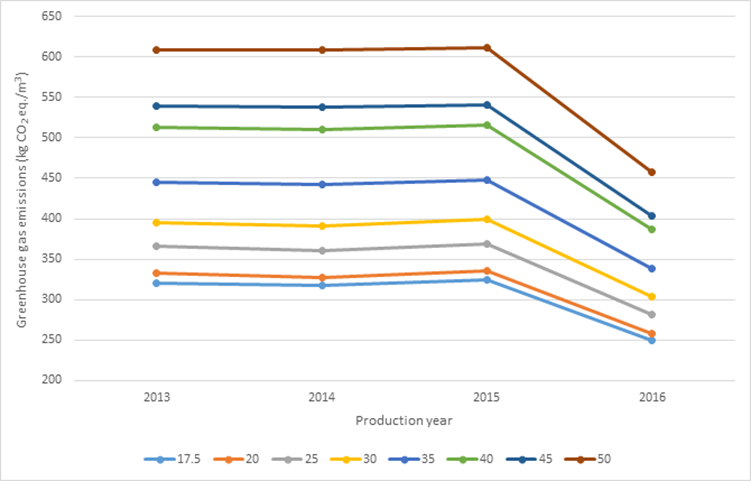

We have used the EPD as an in-house tool for driving process efficiency more than as a marketing tool per-se. It has not generated specific EPD market demand yet, and possibly will not in the near future. We are nevertheless committed to maintaining it as a tool to benchmark our environmental footprint. Our CO2 emissions per m3 of concrete have decreased year on year since we first obtained the EPD (see chart below).

Latest News

EPDs in Transport Infrastructure: A Path to Sustainability with NTRO

The National Transport Research Organisation (NTRO) is championing a resilient and sustainable future through innovative research and practical solutions to transport infrastructure challenges....

A guide to understanding LCAs and EPDs

Understanding the differences between Life Cycle Assessments (LCAs) and Environmental Product Declarations (EPDs) Embarking on a sustainability journey can often feel like navigating...

Leading the way in sustainable procurement on infrastructure projects

This month, we’re delighted to feature Ross Brookshaw, Sustainability Manager of the M80 Ring Road Alliance, as our guest author. Ross brings a...